equipment

Production equipment

Mold development

Die-casting manufacturing

Machining

surface treatment

Testing laboratory

Cold extrusion workshop

Mold Development

The mold manufacturing workshop includes new mold design, mold manufacturing and mold maintenance. The workshop has 30 processing equipment, including 15 precision processing equipment, with a total number of 20 people. The monthly manufacturing scale can reach 20 sets.

Die-casting Manufacturing

The die-casting workshop covers an area of 8000 square meters, with a total of 26 sets of 280T-2000T force equipment, and the monthly production scale can reach 1.5 million pieces. The die-casting technology and scale are leading in the die-casting industry in Taizhou.

Machining

Machining workshop: At present, Huanyu machining workshop is divided into four major metalworking workshops, with 70 CNC machining centers as the main equipment, 13 small giant turning and milling centers imported from Japan, 200 economical CNC machines, 80 customized special machines for various projects, and a monthly manufacturing scale of 1.5 million pieces.

Surface Treatment

Automatic plastic spraying line: Huanyu currently has two automatic plastic spraying lines. The production line is highly automated and the product quality is stable. At present, it can achieve the maximum daily spraying capacity of 100000 pieces

Automatic painting line: Huanyu currently has two automatic painting lines and one manual line, two of which have been put into operation for 22 years. Designed based on the principle of Ω automatic painting, the production line has stable quality and high degree of automation. The monthly spraying scale of the three production lines can reach 800000 pieces.

The anodizing line was founded in 2006 and is the first surface treatment line established by Huanyu. Through more than ten years of efforts, Huanyu has accumulated rich experience in the anodizing process of aluminum products. At present, the anodizing process is mature and the quality is stable, and the monthly processing scale can reach 500000 pieces.

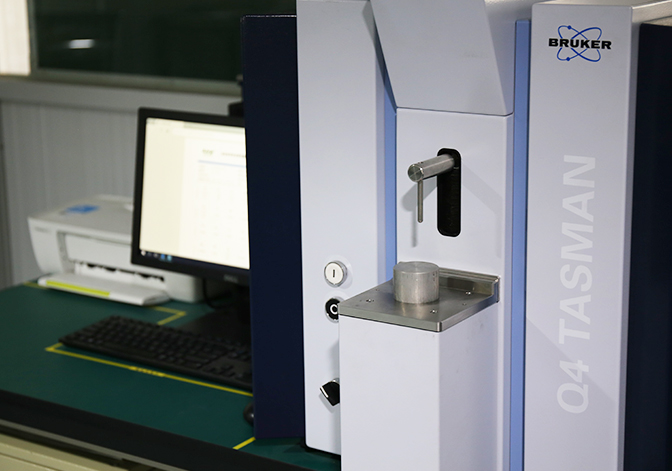

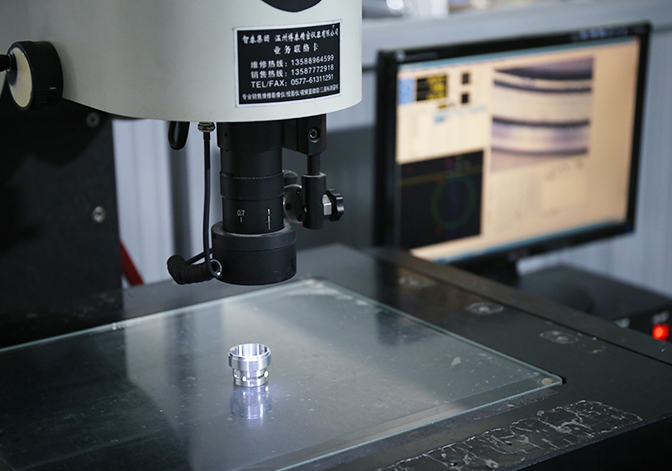

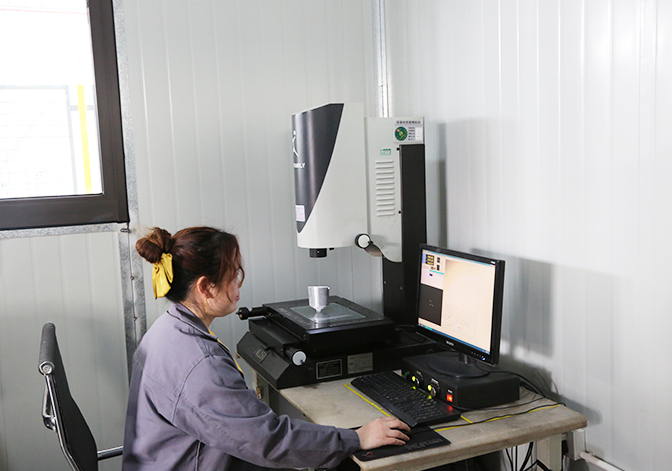

Testing Laboratory

Cold extrusion workshop

The company has 7 sets of cold extrusion equipment from 150-300T, dedicated to the research, development and application of advanced cold extrusion processes, and has accumulated rich experience. Several new energy panoramic imaging cameras developed using cold extrusion technology starting from 2021 have partially entered the mass production stage.